Water and electronics don’t usually mix well together. When a gadget falls into the water, this oftentimes elicits a panic from the person. This means that the item that fell into the water is forever destroyed. This can be such an inconvenience.

The good news is that some scientists have spent time for research and may have come across a method of making electronics from H2O. This could bring about big changes in the field, one that the consumers can look forward to in the future.

Yes, water has become the secret ingredient to create electronics. They use this compound in a straightforward fashion to come up with key components for products such as solar cells, X-ray detectors, and other optoelectronics devices.

Here comes what may be the next generation of photovoltaics, semiconductors, and LEDs. These could be created with the use of perovskites, which is an exciting and versatile nanomaterial with a crystal structure.

It has been discovered that perovskites actually show the same kind of efficiency to silicon. These are a lot more affordable to make as well as feature a tuneable bandgap. The latter simply implies that the energy they are able to absorb, reflect, or conduct can be altered to adapt to the different purposes it may serve.

As mentioned previously, water is often kept as far away as possible when they create perovskites. That’s because the moisture that comes from it can bring about defects that may appear eventually, causing the materials to crumble or disintegrate more quickly when these are used in a device.

Because they need to keep water away, perovskites utilized for scientific research are often created using spin coating in a sealed environment of what they call a nitrogen glove box. However, members of the ARC Centre of Excellence in Exciton Science have discovered a very simple way to control the growth of phase-pure perovskite crystals by using H2O as its positive factor. The best part is that this liquid-based mechanism will work at room temperature, which means that the new method will be cost-effective as well.

The project is led by the researchers who work at Monash University. The team discovered that by changing the ratio of water to solvent during the young stages of the entire process, they would have the choice of growing a variety of perovskite crystals that come with structures that can adapt to different purposes.

“By carefully tuning the concentration of water in the precursor solution, we realized the precise control of particular perovskite phases,” corresponding author, Dr. Wenxin Mao of Monash University, explained.

The computational and thermodynamic analysis that was done by colleagues at the University of Sydney were able to identify and point out that the coordination of lead and bromide ions in the precursor solution. This was crucial for them when it came to determining which kinds of crystals could be formed by the process.

“We now understand the internal mechanics and function of water inside the precursor solution. By doing that we can further use water to control the crystallization process,” lead author Qingdong Lin, a PhD student at Monash University, also said.

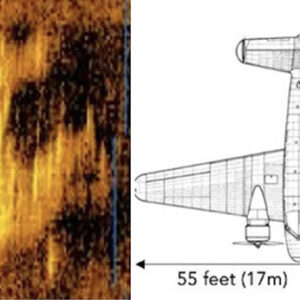

They also needed to test quality of the final product, and to demonstrate how well it worked, crystals produced through this process were coupled with back-contact electrodes via nanofabrication in order for them to make X-ray detection devices.

This test sample worked well and performed just like the commercial X-ray detectors that have been used in the real-world. The same goes for the medical imaging and Geiger counters. These actually performed better than the prototype perovskite X-ray detectors that were made and developed with the use of the slower, more complex fabrication methods.

Wenxin shared, “We compared them with commercial X-ray detectors as well as other types of perovskites and we do have a very good responsivity and sensitivity to X-rays. Overall this project shows that we have found a smart way to control inorganic perovskite single crystals. The methodology is flexible and feasible and doesn’t require a very unique environment or technique to apply it.”

Aside from solar cells, X-ray detectors, and LEDs, these perovskites made using the H2O method could also come in handy with the creation of UV light detection, lasers, and solar concentrators.

This work made had been recently published in Advanced Functional Materials.

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo