The winter season can always be unforgiving. The ice and sleet on the road make travelling dangerous. In fact, those who have important appointments are often times are forced to shuffle their schedules around just so they can wait for the snow to thaw.

More importantly, the ice collects toxins around the environment. When these thaw out, the pollutants reach the ground and harm everything on its path. Hence, scientists have put their heads together to come up with the perfect solution.

Right now, you may have noticed that airports delays have become commonplace. This happens more often during the winter season when jets on the runway need to be dowsed with the use of thousands of gallons of deicing fluids. This helps prevent ice formation and maintain the plane’s aerodynamics. This is also a good way to help alleviate deadly accidents. This happened to the Air Florida flight. It fell into the Potomac River in Washington, DC. It happened right after lift-off in a 1982 snow storm.

While the planes are deemed safe for takeoff, de-icing them means that much of the liquid slides from the surface of the aircraft and ends up on the ground, polluting bodies of water such as streams, lakes, and oceans. Now, scientists have worked hard to create a more efficient product that’s immune to ice for industries such as the airline. A team at the University of Illinois Chicago have come up with a longer-lasting and eco-friendly alternative to what’s already available.

“Glycols dissolve very fast and get washed away before the plane takes off, and it’s a serious problem that costs hundreds of millions of dollars—most of which literally ends up in the drain,” Sushant Anand, assistant professor of mechanical engineering, said. “We thought, why not improve such chemicals themselves, and make alternatives that can last longer while being more biofriendly. And that is what we ended up doing.”

Working with Ph.D. student Rukmava Chatterjee, they were able to achieve their goal. They developed 80 different anti-freezing coatings. These come under different classifications such as polymeric solutions, emulsions, or gels. These can also be easily applied to different surfaces made from aluminum, steel, copper, glass, plastic or any industrial surface. There’s no need for preconditioning or expensive surface treatments to do this.

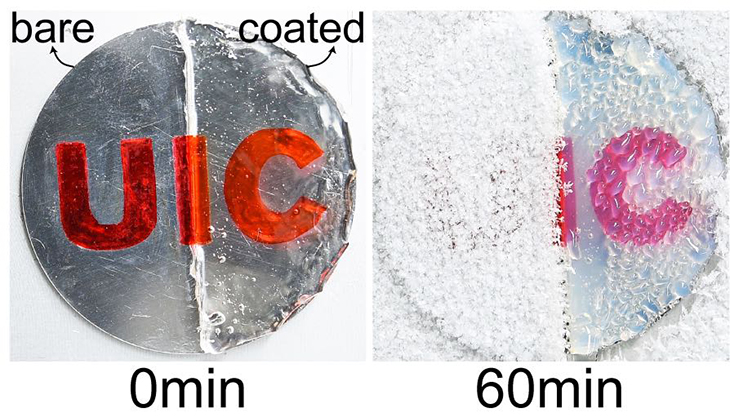

“Our coatings are an all-in-one package which can delay formation of frost for extended hours, and simultaneously cause any ice formed on its surface to easily shed off by a gentle breeze or simple substrate tilting,” Chatterjee said. The anti-freezing gels have been made to be transparent. This is important especially when used for traffic signals, runway lights that assist pilots during landings, automotive windshields, and building windows.

In order to create the product, they worked with phase change materials. They chose this because these had a melting point above the freezing point of water (0 degrees C). Simply put, under sub-zero temperatures, the materials stay in a solid state. This is very much similar to chocolate, butter, and even water.

The multifunctional coatings can stop ice and bacteria from sticking on surfaces no matter the inherent material structure and chemistry. This was designed by regulating how chemicals leach out of the material system and how it creates a lubricating surface layer. The nature of the layer is slippery and it does not freeze.

Chatterjee had spoken to GNN about this. He said that he and his PhD advisor Prof. Anand came into the idea in 2016. “It was February and I was flying out from Chicago to deliver a talk in an international conference on ice/frost protection technologies. Quite an irony! It was a frigid winter day and the flight was already delayed due to icing issues. As a plane full of frustrated passengers waited inside the aircraft for two hours, we watched the plane getting dowsed continuously with thousands of gallons to prepare it for a safe take-off. Later, I missed my next connecting flight due to this delay and had to drive overnight to the conference venue.”

He continued, “Since then we have been researching, formulating compositions & exhaustively testing them under real-life winter conditions to address this long standing issue. Being liquid, all these chemicals get easily dissolved away or sheared off, the moment the flight takes off. Our idea was to use certain materials which are solid when cold.”

“In our latest work we identified a family of these materials and encapsulated them in a polymer matrix. The objective being to preserve their native anti-icing property but to increase their lifetime,” he added. “We prepared more than 80 such formulations in the form of sprayable solutions, emulsions, creams & gels. They can be easily sprayed or coated on any industrial surface (metal/ glass/ plastics) without the need for any special surface treatment.”

“A key point was to use materials which are bio-friendly. For example the anti-freezing gels we prepared are made of dimethyl sulfoxide (a by-product of plant industry and having miraculous medicinal properties) and gelatin (the stuff you use in making deserts and custards): so all very safe items.”

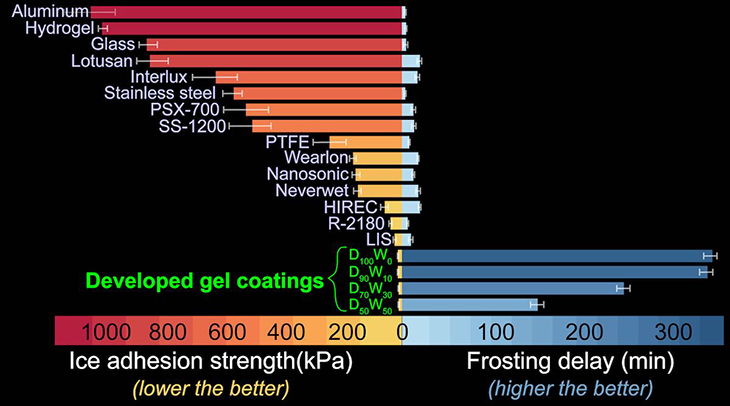

The gels have performed better than the rest. In fact, this had a significant edge against the formulations available in the market. They are very simple to fabricate because you only need two components. Once done, these can be cured/sprayed/painted/coated on any surface quickly and easily. Shape won’t be an issue and even better is that these are optically transparent even when temperatures dip below zero.

Their research has been published in Advanced Materials. Findings show that when compared to commercial coatings of today, the gel works more efficiently by an order of magnitude after exhaustive testing.

Chatterjee explained to GNN how the gels are also anti-bacterial in nature. “Imagine coating your smart-watch (or any wearable electronic) with this gel and using it in winter. It can potentially prevent your watch’s battery from dying in the cold while also preventing it from bacterial contamination, thereby precluding the need for constant sanitization.”

For the aerodynamic testing, the team had coated a propeller blade. They then tested its anti-frosting performance by taking it out in below zero winter conditions. These coatings were also exposed to very high shear airflow, very much similar to a hurricane. The anti-frosting performance was observed after. The more exhaustive testing was also performed on actual airplanes in wind-turbines. This was to make sure that they passed the industrial test requirements before they were exposed to real-life usage. The inventors promised a significant improvement over the commercial solutions our right now.

“Since our anti-icing sprays are bio-friendly and anti-bacterial, we even think there is a potential to use them in agriculture to prevent crops from being ruined by severe frost,” Anand said. “But that is a pipe dream, and we need to do more studies to see if there will be any long-term adverse effect on the plants.”

A worldwide patent application titled “Compositions and Methods for Inhibiting Ice Formation on Surfaces” had already been filed by UIC’s Office of Technology Management.

For more information, watch the video posted below.

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo