For the past 200 years, concrete has been at the core of the planet’s structural development. As time went on, however, people realized that producing concrete is highly unsustainable and today, 5 percent of the world’s greenhouse gases come from concrete production. A larger source of carbon dioxide emissions is when flue gas is emitted from smokestacks in power plants.

A team of researchers at UCLA took this information and created a unique solution for it. Their plan is to capture the carbon from smokestacks before it’s emitted into the environment, and use it to create a totally new building material—CO2NCRETE—using a 3D printer.

The idea makes the production of concrete, or a building material just like it, a closed-loop cycle. It doesn’t create any harmful pollutants and instead, it uses up other pollutants in the process by way of upcycling.

J.R. DeShazo, professor of public policy at the UCLA Luskin School of Public Affairs and director of the UCLA Luskin Center for Innovation, got involved in the project because it could change the way we attack climate change. He said,

“What this technology does is take something that we have viewed as a nuisance — carbon dioxide that’s emitted from smokestacks — and turns it into something valuable. This technology tackles global climate change, which is one of the biggest challenges that society faces now and will face over the next century.”

While DeShazo covers the public policy end of the project and provides economic guidance, a number of professors from different disciplines, such as biochemistry, environmental engineering, materials science, and aerospace engineering, have been the backbone of the science behind the development.

There are many challenges ahead for this idea, such as size scalability and convincing stakeholders to make the huge shift from their coal-burning power plants to this sustainable solution.

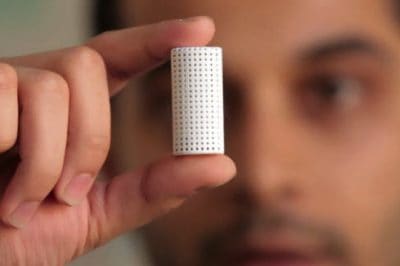

Thus far, the concrete-like building material has only been produced at the lab level in tiny cone-sized pieces. Though the “proof of concept” exists, as DeShazo said, the researchers need to make the material at a larger scale for actual building purposes and figure out how to produce it commercially.

As far as stakeholders go, the researchers would need to convince them that not only is the shift good for the environment, but it’s also good for them as a company. DeShazo said,

“This technology could change the economic incentives associated with these power plants in their operations and turn the smokestack flue gas into a resource countries can use, to build up their cities, extend their road systems.”

There may be many strides before this concept turns into a global reality, but the fact that it can physically be done is a huge accomplishment in itself. The team’s goal is to have this technology assist in places like China and India, the top two greenhouse gas producers in the world.

What are your thoughts on this sustainable technology? Please share, like, and comment on this article!

This article (Researchers Just Turned Carbon Dioxide Emissions Into 3D-Printed Concrete) is free and open source. You have permission to republish this article under a Creative Commons license with attribution to the author and TrueActivist.com